SEND US A MESSAGE

Kindly fill up this form for feedback and quote requests, as well as sending job applications:

Kindly fill up this form for feedback and quote requests, as well as sending job applications:

Mould assembly is where mold parts done by mold making process or via repair are fitting into one mold via crane and will be delivered to customers for finished ones.

Mold milling and grinding are part of process of surface grinding mold parts to ensure smoothness of the mold surface and to eliminate any unnecessary metal parts that can create defects upon a finished product.

In case of a defect in a mold part, whether via CMM or injection mold, the welding department will fix any parts that has caused the defect. This includes any modified mold parts or parts from customers that need repair due to creating NG products.

Before and after mold repairs and for new and modified molds, the plastic injection molding machine is used to test them and to check for any defects before and after the mold was modified.

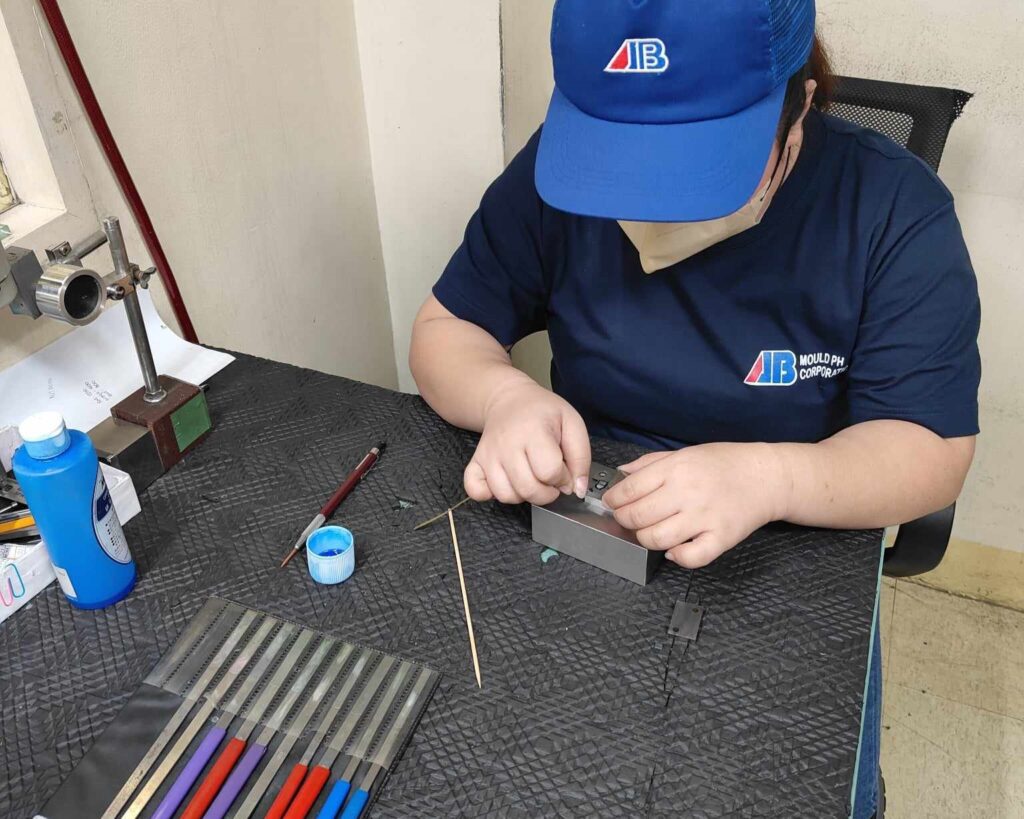

The inspection department are using advanced CMM measuring tools for inspecting finished mold parts, to ensure the accuracy and quality of parts done by the production department. This is one of the crucial process in detecting possible NG parts that might need further repair due to possible errors in mold making.

EDM Die Sink is a process done by a die sink machine in which it creates intricate and complicated cavities in a mold part using an electrode. The cavities done is based on the design needed on a mold part. This is to ensure that even any small and complex mold parts can be done in a mold making process in a very efficient and precise way.

EDM Wirecutting uses a machine using wires as medium to cut through metal molds and used to create holes and other small parts for mold making process. Even any small parts of a mold can be done through wirecutting, ensuring the accuracy and consistency in making molds.

CNC Machining is where programs from programming department are used mainly for rapping and finishing mold parts via a CNC machine. Critical tolerance of tolls used in CNC machines are also strictly followed. This is to ensure mold parts done by the machines are detailed and contribute to the efficiency and productivity of finished molds.

Our mold design and programming staff ensures the quality and efficiency of the mold designs sent by our customers. Mold design is where the mold is shaped via CAD software so the final product can be created efficiently, accurately, and most importantly, without any defects. Mold programming is where the inputs of a CNC program for a mold is done by a CAD software that can generate such programs for CNC machines to read and use. Both operations are critical in the mold-making process as this will ensure the molds done by staff can lead to better production value and great quality of the finished products.

AB Mould Ph Corporation is an injection mold manufacturing company that creates and specializes in producing various products for the electronics and automotive industries. It includes designing, assembling and manufacturing of molds.

AB Mould Ph Corporation is committed to surpassing customer expectations and developing our factory into a reputable, competitive, and responsible enterprise.

Our unwavering pursuit is to create greater value for our customers.

AB Mould PH Corporation is a company based in Dasmarinas City, Cavite, Philippines. They specialize in the design, manufacturing, and maintenance of injection molds and plastic molds. Their services include mold design, modeling data creation, CNC programming, mold production, and mold maintenance. AB Mould PH Corporation is known for their expertise in injection molding, prototype mold production, industrial design model production, 3D modeling data creation, and product design. They are committed to providing high-quality mold solutions and supporting the manufacturing industry.

The company has started operations on March 22, 2013 as a Philippine branch of AB Co., Ltd., currently located in Unit C Lot 9, Block 7, First Cavite Industrial Estate (FCIE), Dasmarinas, Cavite, 4114 Philippines.